MAINTENANCE AND REPAIRS

MAINTENANCE AND REPAIRS

Maintenance and repairs on MV/LV transformers

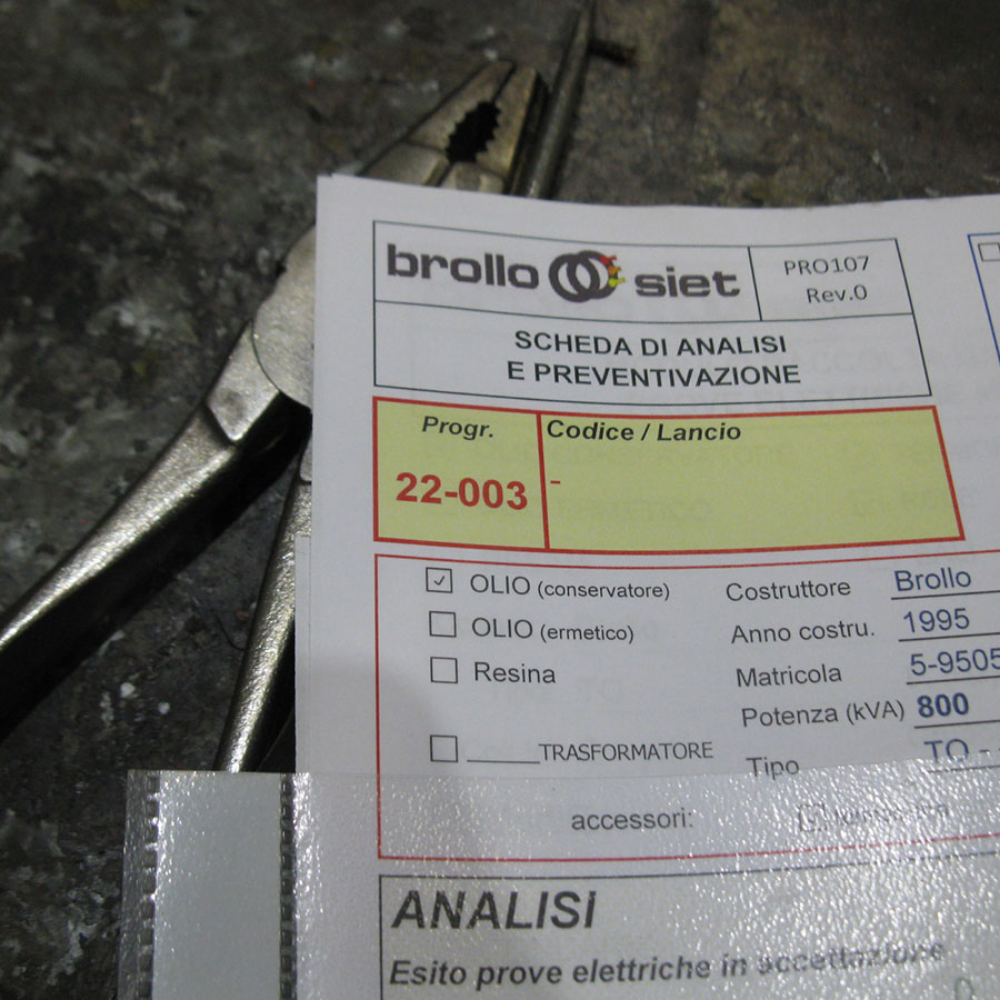

Brollo Siet offers a maintenance service to be carried out on MV/LV transformers, both in oil and in resin, to guarantee functionality. at the highest levels, avoiding downtime and unexpected costs, as well as to ensure the safety of people. Scheduled maintenance, also required by the CEI 78-17 regulation, ensures maximum reliability of operation of the transformers over time.

Maintenance

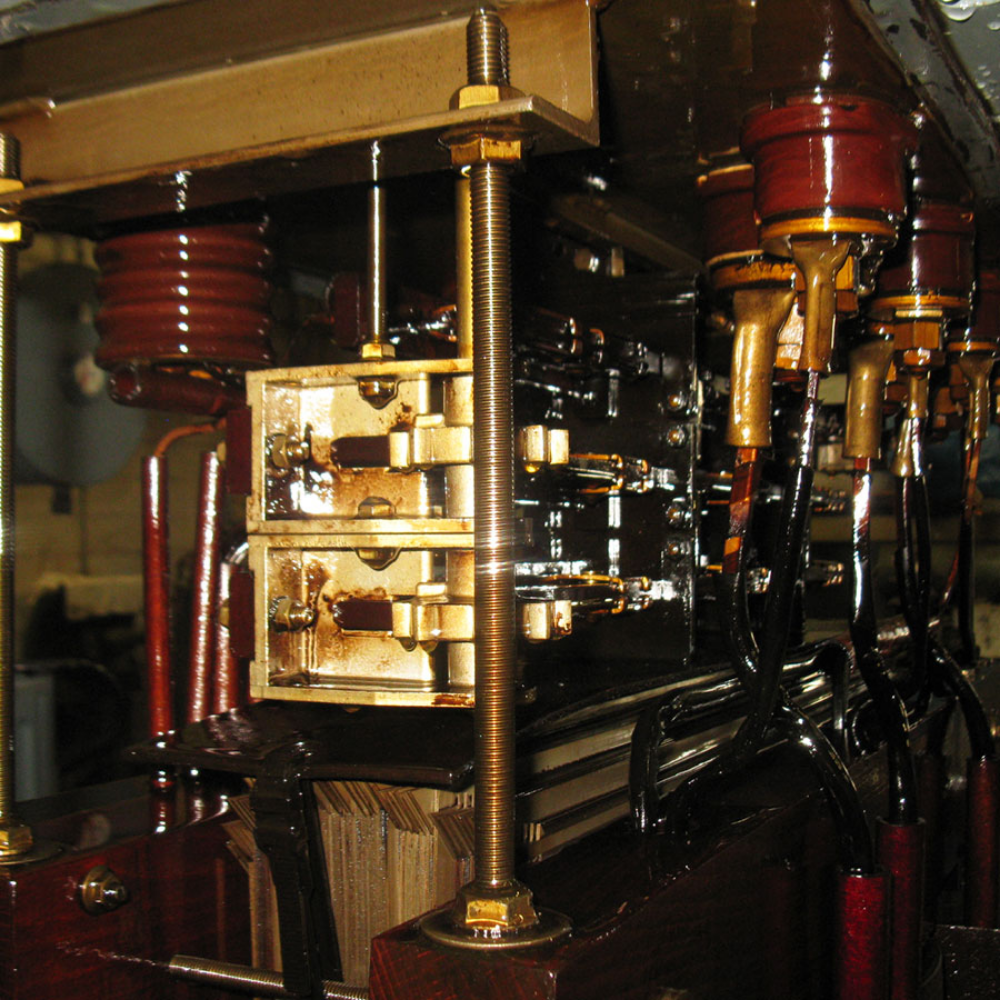

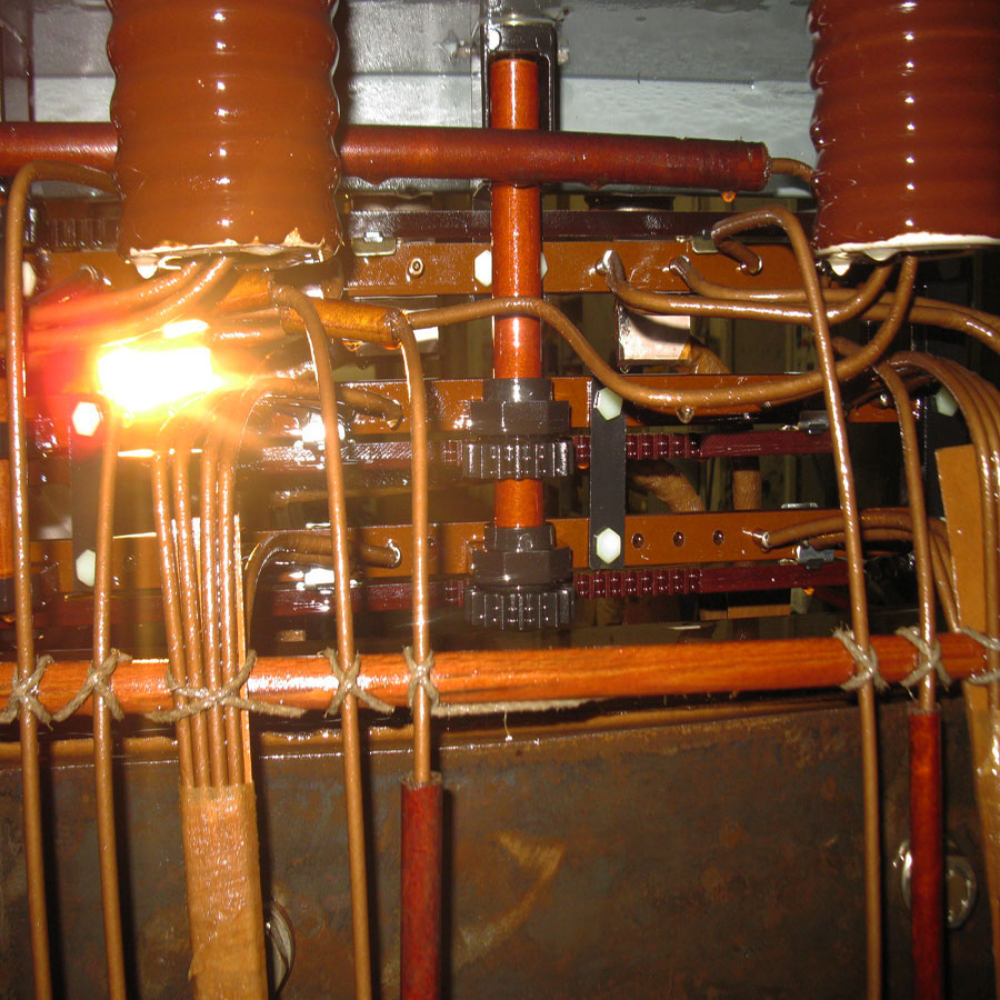

OIL TRANSFORMERS WITH CONSERVATOR

By taking an oil sample from the lower tap of the transformer and subsequent analysis, the conditions of the dielectric fluid are determined. Depending on the outcome of the test, it may be necessary to:

- The oil treatment which has the function of filtering the oil from any impurities (microfiltration), remove the dissolved gases (degasification) and eliminate the water in suspension or in solution (drying or dehumidification), in order to restore the value of the rigidity dielectric to those required by the CEI EN 60422, CEI 10-43 standard.

- Oil replacement which has the function of completely replacing the oil contained inside the transformer, after washing the inside of the box and the extractable part. In addition to the activities described above, other checks are carried out to ensure that the transformer is in good working order:

- - Level control and, if necessary, topping up to the optimal level;

- - Check oil leaks from the seals and replace them in case of deterioration;

- - Checking the state of the salts and possible replacement;

- - Cleaning of the insulators and checking the state of conservation and possible polishing of the pins;

- - Check the operation of the accessories (Buchholz relay and thermometer).

HERMETIC OIL TRANSFORMERS

In hermetic transformers the oil oxidation process is negligible; therefore, we do not recommend taking oil samples for analysis. Maintenance mainly concerns maintenance activities. visual inspection. If particular problems arise, such as oil leakage or safety device interventions (DGPT, RIS, etc.), it is It is necessary to carry out an in-depth analysis.

RESIN TRANSFORMERS

The transformer embedded in resin does not require of particular maintenance; in any case it is It is best to monitor and carry out the operations listed below at least once:

- Cleaning of cooling channels

- Bolt tightening check

- PT100 probe control

- Check the operation of ventilation bars, if installed

REPAIRS

Thanks to the technical experience acquired over time, we carry out any type of repair, both on oil transformers and resin transformers, of any manufacturer and production year. After having verified the fault of the transformer through a pre-test, the most economically viable solution is evaluated together with the customer. advantageous and technically more reliable; if the repair is not carried out, exchanges and/or scrapping may be considered.

OIL TRANSFORMERS

Reconstruction of damaged MV and LV windings;

Overhaul or replacement of the switch;

Oven drying of the fruit;

External painting of case and lid;

Replacement of the MV and LV insulators;

Replacement of safety devices;

Expansion tank application (conversion from hermetic transformer to transformer with conservator);

RESIN TRANSFORMERS

Reconstruction of damaged MV and LV windings;

Renovation of the triangle bridge;

External drying of the core;

Replacement of reel supports;

Painting of the core and transformer

Technical features

Customization

Technical features

Manuals and attachments